New Solvent Tank Farm for Tor Coatings Limited

The Company

Tor Coatings are one of the UK market leaders in the design and manufacture of interior and exterior building protection products. A subsidiary of RPM International Inc., one of the world’s largest coatings groups, Tor Coatings is one of the leading provider of flame-retardant coatings in the UK

Tor Coatings are one of the UK market leaders in the design and manufacture of interior and exterior building protection products. A subsidiary of RPM International Inc., one of the world’s largest coatings groups, Tor Coatings is one of the leading provider of flame-retardant coatings in the UK

Project Brief

- Design, construct, install and commission a new solvent tank farm and distribution facility, suitable for up to 300,000 litre solvent capacity

- Strip out and demolish existing solvent tank farms

Scope of Works

To design, procure and project manage the following:

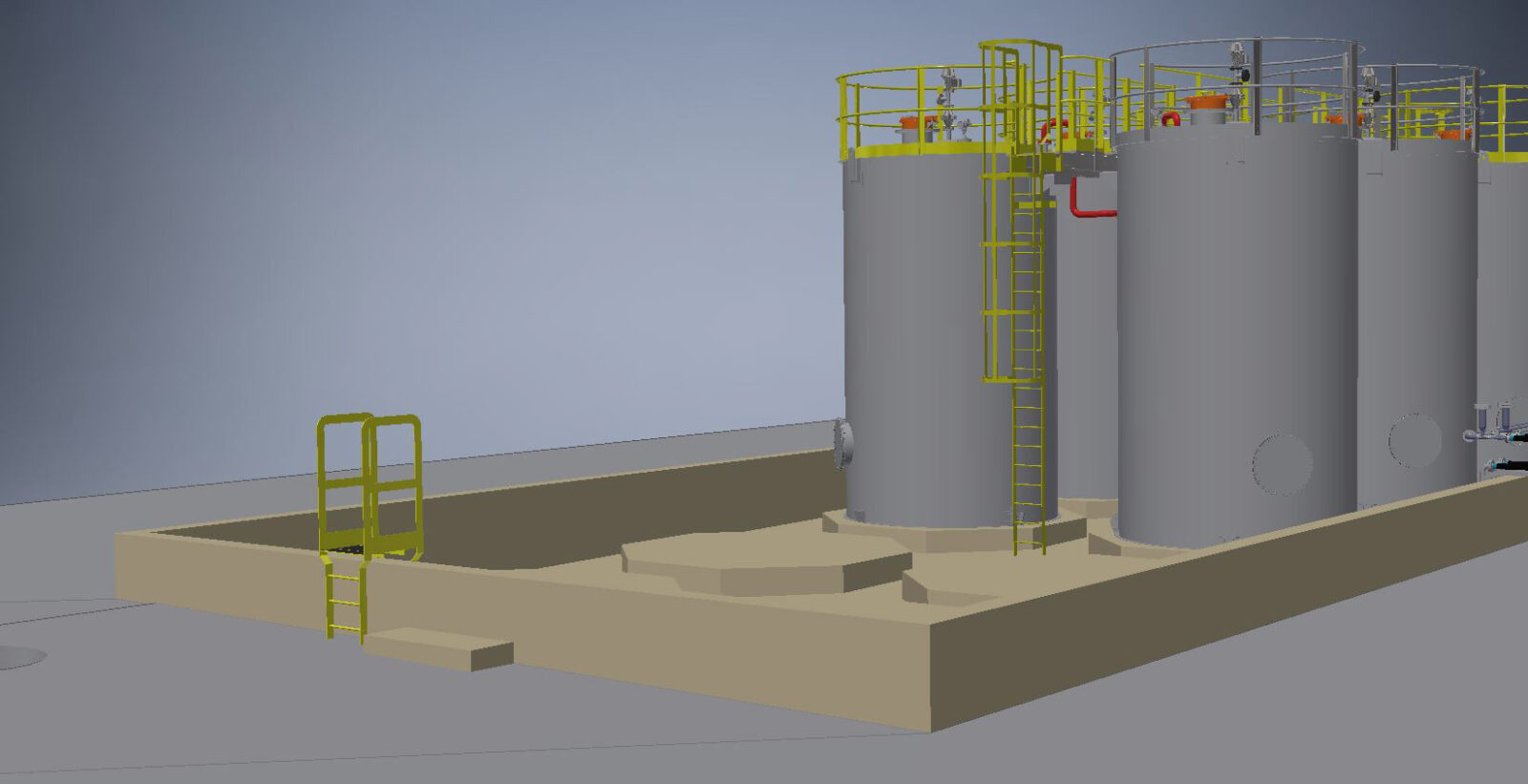

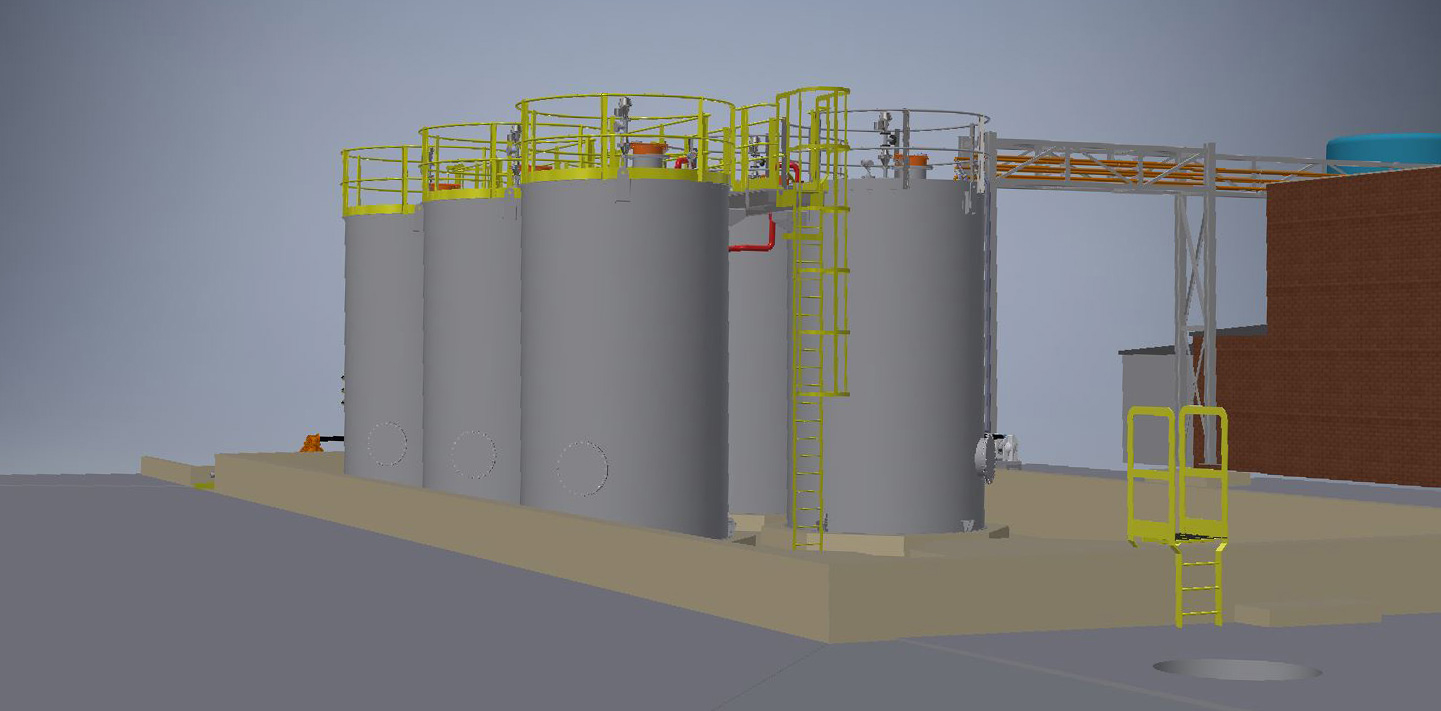

- Front End Engineering Design Study including: 3D designs, P&ID’s, General Arrangement layout drawings, equipment specification and costing

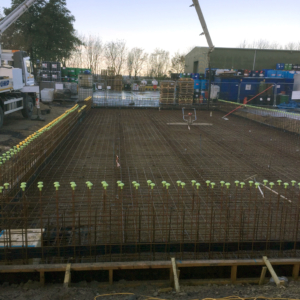

- Geotechnical survey of existing ground conditions

- Civils design and construction of tank farm bund and surrounding ground area

- Installation of 6 x 30,000 litre storage vessels

- Supply and installation of process infrastructure including process control, instrumentation, electrical, mechanical including pumps, valves and pipework

- Installation of pipe bridge to manufacturing

- Demolition & removal of existing low flash and high flash tank farm

Design Challenge

The main challenge for Ai Process was to maintain existing site operations including solvent transfer to production, and seamless transfer of operations from old to new tank farm, without affecting production at any stage. Core challenges also included Ai having to:

- Locate a suitable area large enough for the new tank farm, that conforms to boundary and building distance regulations

- Work safely within the ATEX environment at site

- Design additional process safety measures in order to meet group requirements such as:

- VOC gas detection within the bund

- Sprinkler system within bund and surrounding the tanker loading area

- Ensure project completion to an agreed budget, within the proposed time constraint

Design vs Actual — Move the slider