Process improvements for paint manufacturer Jotun Paints

The Company

The Jotun Group is a leading supplier of paints and powder coatings. The Group has 65 companies and 39 production facilities on all continents. Jotun is represented in over 100 countries. They supply paints and coatings that have been specially developed for unique conditions.

The Jotun Group is a leading supplier of paints and powder coatings. The Group has 65 companies and 39 production facilities on all continents. Jotun is represented in over 100 countries. They supply paints and coatings that have been specially developed for unique conditions.

Project Brief

- upgrade of existing production capability

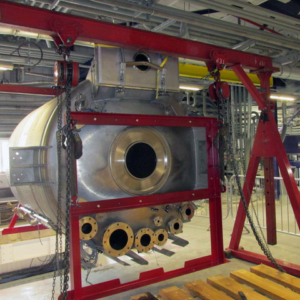

- installation of two new bulk dispersion mixers and one bead mill

Scope of Works

To design, procure and project manage the following:

- Information gathering, evaluation and designs

- Detailed site & equipment measuring, drawing designs and revisions

- Preparation of process plant and service plant specifications

- Procurement of process plant and service plant

- Off site equipment inspections and FAT’s

- Preparation of method statements, risk assessments & Health & Safety file

- Internal project review, client & supplier contract meetings

- Administration and miscellaneous works

- Site supervision of contractors

- System commissioning and hand-over

- Operator Training

Design Challenge

The main challenge for Ai Process was to correctly identify a suitable location for the new equipment installation in a congested production area, whilst ensuring minimal disruption to production. Careful project planning and co-ordination of various trades was crucial.

Key considerations were:

- Identify a suitable location for the two new bulk dispersers and one bead mill, based on:

- accessibility for the new equipment

- operator process flow once the equipment had been installed

- ‘Make it fit’ – once the location had been agreed, there was a need to ensure that the new equipment would fit.

- Manoeuvre equipment into desired location in the middle of a busy production facility surrounded by working mixers and other equipment restricting access for the large bulk mixers.

- ATEX environment – which added another degree of difficulty for the design, planning and execution of the project.

N.B. Additional caution is ALWAYS required when operating in explosive environments, especially as tools required to complete the work could produce sparks and be a source of ignition. Consequently, special work permits and additional attention to detail is required for risk assessments and method statements.