Manufacturing facility rebuild following a factory fire

The Company

ITAC is a British Manufacturing company, established in 1902, that specialises in the production of specially formulated adhesives and coatings for the construction, roofing, flooring and food industries throughout the world. ITAC also offer confidential toll manufacturing services for a wide range of organisations within the adhesives and coatings sector.

ITAC is a British Manufacturing company, established in 1902, that specialises in the production of specially formulated adhesives and coatings for the construction, roofing, flooring and food industries throughout the world. ITAC also offer confidential toll manufacturing services for a wide range of organisations within the adhesives and coatings sector.

Project Brief

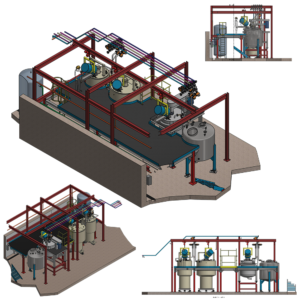

In 2015 ITAC suffered a fire that significantly disrupted production throughput and destroyed much of their manufacturing capabilities.

Ai Process were appointed to design and project manage the rebuild and upgrade of ITAC’s production facility, ensuring an expansion of production throughput to be significantly higher than pre-fire production. The project also included the installation of a new highly flammable tank farm and new manufacturing equipment in an ATEX environment.

Scope of Works

- Factory design to allow for future production growth

- Factory layout redesign to incorporate new equipment and to emphasise good process flow

- New manufacturing equipment

- New bulk storage and transfer of highly flammable material

- Automated process for accuracy and repeatability

- Controlled ventilation system designed to maintain air temperature and pressure throughout the factory

- Large emphasis on health and safety legislation, including ATEX rated equipment

Design Challenge

Despite ITAC’s excellent track record on health and safety, the nature of the materials that are stored and handled on site are such that a small amount of static was the direct cause of the blaze – putting further emphasis on how easy an incident like this can happen and how important it is to take the necessary precautions to minimise the risks in these types of working environments.