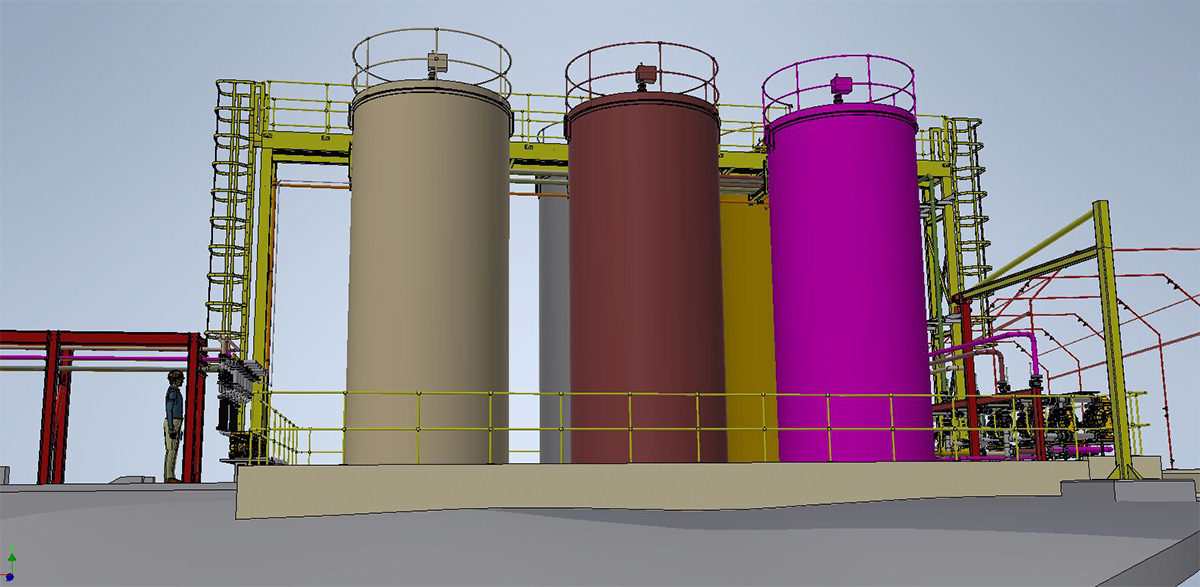

Ai Process design & install new solvent tank farm and solvent transfer system at Bostik

Client Key Facts

- Name: Bostik

- Industry: Adhesives & Sealants

- Established: 1889

- Employees: 6,000+

- HQ Site: Colombes, France

- Project Site: Stafford, UK

As Bostik seek to continuously improve their sustainability, they employed the services of Ai Process as Principal Contractor to design, install and commission a new solvent tank farm and solvent transfer system on a turnkey basis.

Timelapse Video – Press play

To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video

Scope of Works

- Demolition of existing buildings

- Civils and ground works

- Bund casting

- Vessel fabrication & installation

- Solvent transfer pipebridge

- Process infrastructure

- Sprinkler systems

- Vapour recovery system

Ai Process Services

- Detailed engineering designs

- User Requirement Specification

- Front End Engineering Design Study

- Process optimisation

- Procurement

- Cost control

- Project management

- Commissioning

Design vs Installed — Move the slider

Conclusion

Bostik sought to increase site sustainability via a bespoke solvent storage solution that complied to modern storage regulations and that could be constructed within their manufacturing site while causing minimal operational disruption. The successful project improves the site in a variety of ways, including improved sustainability for Bostik as they benefit from the use of a vapour recovery system and a reduction in site deliveries.